Material Master Tables In Sap

Dear All,

There is a complete listof SAP MM basic tables

Maintenance of planning strategy group in material master - the planning- strategy gp (MRP2 view) for material master is currently left blank for all semi-finished (37. level) items - as such, both requirements are taken into account - SAP personnel has advised that maintaining the strategy group 52 would sol=. LFM2, Vendor Master: Purchasing Data (Plant, Vendor sub-range). MARA, Material Master: General data. MAKT, Material Master:.

Material Master Data:

MARA – General Data, material type

MAKT– Short Texts, descriptions

MARM– Conversion Factors

Total war: attila best overhaul mods. MVKE – Sales Org, distribution channel

MLAN – Sales data, tax indicator, tax

MARC – classification

MBEW – Plant Planning Data

MLGN – Valuation Data

MLGT – Warehouse Management Inventory Data

MVER – Warehouse Management Storage Type

MAPR – Data

MARD – Consumption Data

MCHA – Pointer for Forecast Data

MCHB – Storage location data

Purchasing:

EKPO– Purchasing Document Item

EKKO– Purchasing Document Header

EBAN– Purchase Requisition

EKBE– History per Purchasing Document

EKET– Scheduling Agreement Schedule Lines

EINE– Purchasing Info Record: Purchasing Organization Data

EKKN– Account Assignment in Purchasing Document

EINA– Purchasing Info Record: General Data

EKES– Vendor Confirmations

EBKN– Purchase Requisition Account Assignment

EORD– Purchasing Source List

T024– Purchasing Groups

EKBZ– History per Purchasing Document: Delivery Costs

AMPL– Table of Approved Manufacturer Parts

EKAN– Vendor Address: Purchasing Document

Inventory Management:

MSEG– Document Segment: Material

MKPF– Header: Material Document

RESB– Reservation/dependent requirements

MARI– Short document: material movement

ISEG– Physical Inventory Document Items

RKPF– Document Header: Reservation

T156– Movement Type

IKPF– Header: Physical Inventory Document

T156T– Movement Type Text

CHVW– Table CHVW for Batch Where-Used List

T156SY– Mvt Type: Qty/Value Update: System Table; Rel. 4.6A

MMIM_REP_PRINT– Print Settings, Reporting MM-IM

T156S– Movement Type: Quantities/Value Posting (Until Rel. 4.5B)

T156W– Posting string values

T156M– Posting String: Quantity

Invoice Control:

RSEG– Document Item: Incoming Invoice

RBKP– Document Header: Invoice Receipt

BSIM– Secondary Index, Documents for Material

RKWA– Consignment Withdrawals

RBCO– Document Item, Incoming Invoice, Account Assignment

RBKP_BLOCKED– Logistics Invoice Verification: Blocked Invoices

RBKP_V– Generierte Tabelle zu einem View

Unifying software for mac. Logitech Unifying Software Vs 5.1 appeared in my MacUpdate list today. After installing it on a 2017 Retina iMac running High Sierra, I got the msg that the app was not compatible with my iMac system.However, It appears that I can configure a Logitech device via via SteerMouse payware with separate profiles for a Logitech G5 laser gaming mouse. And an ergonomic mouse from JTech.

V_169P_MB– Generierte Tabelle zu einem View

T149D– Global Valuation Types

RBDRSEG– Batch IV: Invoice Document Items

RBTX– Taxes: Incoming Invoice

RBWS– Withholding Tax Data, Incoming Invoice

RBKPB– Invoice Document Header (Batch Invoice Verification)

RBDIFFKO– Invoice Verification – Conditions

RBEX– Persistent Key Figures Header and Item

- SAP MM Tutorial

- SAP MM Useful Resources

- Selected Reading

SAP R/3 works on real-time data, i.e., there is no time lag between data entry and data availability. The important thing while creating any data is to maintain data integrity. SAP R/3 data is categorized into two −

Master data − Data that is created centrally, and is valid for all applications. It remains constant over time but we need to update it on a regular basis. For example: Vendor is a type of master data that is used for creating purchase orders or contracts.

Transactional data − Data that is associated with processing of business transaction is transactional data.

SAP Master Data is of the following two types −

Material Master Data

Vendor Master Data

Material Master Data

The key points to note about material master data are as follows −

This is the enterprise main source of material-specific data. This data will include information on the materials that a company can procure, produce, store, or sell.

Since there are different departments in an enterprise and each department works on some specific material, they will enter different information regarding their material. So, each user department has its own view of the material master record. The data screens that are used to create material master can be divided into two categories −

Main Data − This will include basic data (base unit of measure, weight), purchasing data (over tolerance and under tolerance), accounting data (standard price, moving price).

Additional Data − This will include additional information like short description about material, currency etc.

Material master has four characteristics, which we will discuss one by one in the following sections.

Material Types

Materials with some common attributes are grouped together and they are assigned to a material type. It differentiates the materials and allows organizations to manage different materials in a systematic manner in accordance to a company’s requirement. For example, raw material and finished products are some of the material types. Material type can be created by following the steps given below.

Path to create material type

IMG ⇒ Logistics General ⇒ Material Master ⇒ Basic Settings ⇒ Material Types ⇒ Define Attributes of Material Types

TCode: OMS2

Step 1 − On the Display IMG screen, select Define Attributes of Material Types, by following the above path.

Step 2 − Click the New Entries button.

Step 3 − Fill in the required information such as name of material type and description. Click on Save. A new material type will be created.

Material Groups

Material group is a wider range of material type. Materials with some common attributes are taken together and they are assigned to a material group. For example: We have some materials that are to be packaged, so the material type can be electrical or food products, but we can group these material types and put them in the packaged material group. Follow the steps given below to create a Material Group.

Path to Create Material Group

IMG ⇒ Logistic General ⇒ Material Master ⇒ Settings for Key Fields ⇒ Define Material Groups

TCode: OMSF

Step 1 − On the Display IMG screen, select Define Material Groups, by following the above path.

Step 2 − Click the New Entries button.

Step 3 − Enter the name of the material group along with its description. Click the Save button. A new material group will be created.

Number Range

When we create a material master record, every material is recognized by a unique number that is known as the material number. We can assign a number to a material through two ways −

External number assignment − While creating a material, you have to enter your own number (containing alphabets or digits), and that should be unique.

Internal number assignment − While creating a material, you need not enter any number. The system automatically generates a unique number to that material.

Define Number Range −

Internal number range can be defined by following the steps given below −

Path to Create Number Range

IMG ⇒ Logistic General ⇒ Material Master ⇒ Basic Settings ⇒ Material Types ⇒ Define Number Range for Each material Type

TCode: MMNR

Step 1 − On the Display IMG screen, select Define Number Range for Each Material Type, by following the above path.

Step 2 − Click the Intervals button.

Step 3 − We can define a number range here and EXT (external tab, if it is checked, then an external number can be assigned in that material). Click the Save button. Number Range is now defined for the material.

Assignment of Number Range

After defining, we need to assign it to a material group. Follow the steps given below to assign a number range.

Step 1 − On the same screen, select the Groups tab.

Step 2 − For a particular material group, we can assign a number range here. Click on Save. The number range is now assigned to the material group.

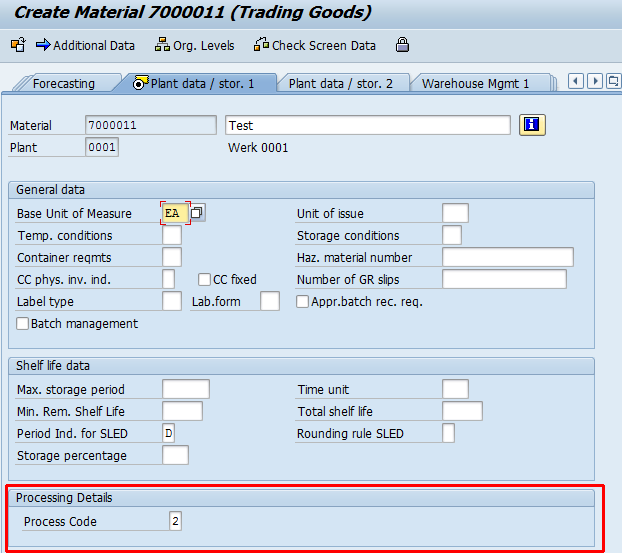

Material Master Creation

Material master contains information on all materials that a company procures, produces, or sells. It contains central data that is available at all the levels. Follow the steps given below to create a material master −

Path to Create Material Master

Logistics ⇒ Materials Management ⇒ Material Master ⇒ Material ⇒ Create Material

TCode: MM01

Note − For any create transaction, we use 01, for edit 02, for display 03 as suffix.

Step 1 − On the SAP Menu screen, click the create button by following the above path.

Step 2 − Fill in all the required details such as material number (if external number assignment), material type, industry sector, etc.

Step 3 − Select the views you want to maintain for your material.

Step 4 − Enter the name of the plant and the storage location.

Step 5 − Enter the required information in your material views such as unit of measure, currency, standard price, moving price, etc. Click on Save. A new material will be created.

Vendor Master Data

The key points about vendor master are as follows −

Vendor Master Data is the enterprise main source of vendor-specific data. It includes information on vendors from which a company can procure, or can sell.

A vendor master record contains information such as vendor's name, address, etc.

Data in a vendor master record is divided into three categories −

General Data − General data is maintained at client level and it is valid for all organizational levels.

Accounting Data − Accounting data is maintained at company level and it is valid for all plants belonging to that company.

Purchasing Data − Purchasing data is maintained at purchasing organization level.

Vendor master has three characteristics, which we will discuss one by one in the following sections.

Vendor Account Group

Vendors are categorized according to their requirements. Some of the vendors having similar characteristics are grouped together and placed in one category. For example, all local vendors can be placed under one account group. Create a Vendor Account group by following the steps given below.

Path to create Vendor Account Group

IMG ⇒ Logistic General ⇒ Business Partner ⇒ Vendors ⇒ Control ⇒ Define Account group and field selection(vendor)

TCode: OBD3

Step 1 − On the Display IMG screen, select Define Account Groups and Field Selection (Vendor), by following the above path.

Step 2 − Click the New Entries button.

Step 3 − Fill in all necessary details such as name of account group, general data, and field status. Click the Save button. A new Vendor Account Group will be created.

Number Range

When we create a vendor master record, every vendor is recognized by a unique number known as the vendor number. As in the case of material master, we have external as well as internal number assignments for vendor master.

Define Number Range:

Number range can be defined by following the steps given below −

Path to create Number Range

IMG ⇒ Logistic General ⇒ Business Partner ⇒ Vendors ⇒ Control ⇒ Define Number Range for Vendor master record

TCode: XDN1

Step 1 − On the Display IMG screen, select Define Number Range for Vendor Master Record, by following the above path.

Step 2 − Click the Intervals button. It will create a number range for the customer account.

Step 3 − Click the Insert button.

Step 4 − We can define a number range here and EXT (external tab, if it is checked, then external number assignment can be done in that vendor). Click on Save. A new Number Range will be created.

Assignment of Number Range

After defining a number range, we need to assign it to a vendor group. Follow the steps given below to assign the number range.

Step 1 − On the same screen as shown above, select the Number Range tab.

Step 2 − For a particular vendor group, assign a number range here. Click on Save. Number range is now assigned to the vendor group.

Creation of Vendor Master

Vendor Master contains a list of vendors from where a company can procure or sell goods. A Vendor Master can be created by following the steps given below −

Path to create Vendor Master

SAP Menu ⇒ Logistics ⇒ Material Management ⇒ Purchasing ⇒ Master Data ⇒ Vendor ⇒ Central ⇒ Create

TCode: XK01

Step 1 − On the SAP Menu screen, select Create for Central Vendor Data, by following the above path.

Step 2 − Fill in all the required details such as company code, purchasing org, and vendor number (if external number assignment).

Step 3 − Fill in all the details of vendor’s address such as street name, postal code, country.

Step 4 − Fill in the necessary bank details of the vendor.

Step 5 − Fill in the necessary accounting information of the vendor.

Step 6 − Fill in the terms of payment that are defined between the company and the vendor. Click on Save. A new vendor master will be created.