5209 New Idea Disc Mower Owners Manual

Agri Supply is proud to stock a wide selection of Disc Mower Parts along with our huge variety of agriculture, gardening, cooking and outdoor products. We stand behind all 26,000 items we sell with our Satisfaction Guarantee. Customer Service is the cornerstone of our family business, and has been for over 50 years. Sloan Express stocks a wide variety of aftermarket ag parts equivalent to the OEM part for agricultural equipment. Our current parts offering includes a wide range of over 8000 parts to fit combines, tractors, hay equipment, planters, sprayers, tillage equipment and more.

Up front apologies if this topic has been covered and I missed it in my search. I may need to transport a New Idea 5209 disc mower 300 miles and am looking at ways of doing it. Narrow roads and distance make towing behind pickup seem unlikely.

New Idea 5209 disc mower conditioner was 4.9 mph (7.9 km/h). Average continuous work rate was 5.5 ac/h (2.2 ha/h). Quality of Work: The performance of the New Idea 5209. 527091 CW CUTTERBAR MODULE GEARBOX ASSEMBLY FOR NEW IDEA 5209, 5212, 5407, 5408, 5409 CASE IH 3309 DISCBINE DISC MOWER.

Next option would seem to be put crossways on 81/2' wide flatbed with overhang. It specs to be 11' wide. Civil service exam nj study guide 2015.

This doesn't seem the greatest either. So I'm looking at loading on trailer and removing tongue and pto shafts. How difficult is that? Anyone know the process of removing the tongue? The seller does not have a loader but may be able to borrow one.

Not sure on how I will push mower on to the trailer from the sides either. It doesn't seem to be that heavy about 3500 lb.

So car hauler ramps may work. This will be a toolbox only operation with no air tools etc to help.

Maybe not the right way to go either? Thanks if anyone has ideas.

Doubt I'm the first person to need to move one of these a fair distance. I bought my New Holland 1411 in Delaware and trailer-ed it 250'ish miles home. My original thought plan was to remove the tongue like you are thinking, but I found it to be much easier than that. This may work for the 5209 as well. I put the left side trailer wheels in a small valley that reduced the ramp angle a bit. The seller had a 50 hp Kubota with a loader. I used it to back the discbine up a set of heavy duty aluminum ramps onto the side of the trailer.

I then lowered the head all the way, and unhooked with the tongue jack on the ground. I removed both the front and mid PTO shafts - I think it was 6 bolts total. Then I simply pulled the swing cylinder pins and laid the cylinder on padding on the head. I then looped a chain in the hitch, and placed a pin & clip in the hitch as a safety measure so the chain couldn't slip off, connected to the loader bucket of the Kubota, and folded/pivoted the entire hitch in against the head and lowered it onto the trailer deck. I used a 102' trailer, and it was a very nice fit.

I loaded in the rain, so I'm not sure I took any pics of that process, but I may have taken one of the load I'll see if I can find. I bought my New Holland 1411 in Delaware and trailer-ed it 250'ish miles home. My original thought plan was to remove the tongue like you are thinking, but I found it to be much easier than that.

This may work for the 5209 as well. I put the left side trailer wheels in a small valley that reduced the ramp angle a bit. The seller had a 50 hp Kubota with a loader. I used it to back the discbine up a set of heavy duty aluminum ramps onto the side of the trailer. I then lowered the head all the way, and unhooked with the tongue jack on the ground.

I removed both the front and mid PTO shafts - I think it was 6 bolts total. Then I simply pulled the swing cylinder pins and laid the cylinder on padding on the head.

I then looped a chain in the hitch, and placed a pin & clip in the hitch as a safety measure so the chain couldn't slip off, connected to the loader bucket of the Kubota, and folded/pivoted the entire hitch in against the head and lowered it onto the trailer deck. I used a 102' trailer, and it was a very nice fit. I loaded in the rain, so I'm not sure I took any pics of that process, but I may have taken one of the load I'll see if I can find. I don't think this will work since the pivoting end of the tongue is set back in box on the frame. Pivoting the tongue like you said would cause you to bend out the side of the box. I have the owners manual for my CaseIH 3309 at home and I believe the back of the manual talks about assembling the mower from the factory. I'll check the service manual I have as well.

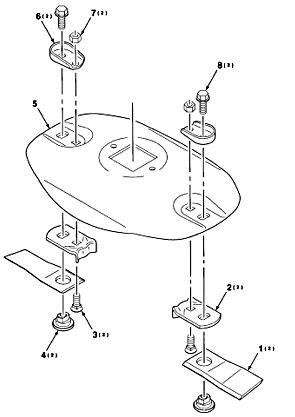

I know they don't ship them with the tongue installed, so it should come off fairly easy. According to the parts breakdown the pivot pin is held in with a nut or nuts (see diagrams). The PTO driveline should be able to be dropped off either by unhooking it from the splined gearbox shaft or by disassembling the slip clutch. I think it is a 'standard' bolt in a groove attachment to the splined shaft, but it may take some persuasion to get it off. Download buku dale carnegie bahasa indonesia pdf.

The slip clutch uses socket head screws if you choose to go that route. If you do take it off, it might be a good time to check the bushings for the pivot pin as well as the frame at the top of the post that runs down to the tire. That was an area that was prone to cracking.

I still need to have mine welded up from last year, my neighbor did a patch job on it to get me through the season, but it really needs to be ground down and done right. 45.11KB 0 downloads. No, that tongue will not fold. This is how I would do it. Back it sideways on the trailer. The tongue will hang over the side at this point giving you some vertical leeway to aid in removal. Lower the header and secure the machine to the trailer at the axles so it can still pivot vertically.

At this point, unless you have a high semi trailer there will still be some tension on the tongue. The key is to eliminate the tension so the tongue pivot pin stops binding. Contoh program inventory berbasis webkinz 2017. One way to do this is to remove the front pin in the tilt turnbuckle,(this must be done very carefully as there may be significant pressure on the turnbuckle pin) install a longer pin, attach a chain and lift until there is no tension on the tongue. Unless the pin is rusted, which is unlikely because of the fiber bushings that should be between the pin and frame, you should be able to pry the pin up and out.

Two strong men can manhandled the tongue out of the pivot but a loader is much desired. Thanks to all.

5209 New Idea Disc Mower Owners Manual

Discbinedr - about what size is the longer pin I'll need? Lifting the tongue will cause the machine to pivot on the axles right? Will the cutter bar or head stay in contact with the trailer floor while lifting the tongue?

If not - do I chock it as I lift the tongue? I need to go look at the machine with your suggestions as I'm doing this from memory. Think there would be clearance to get cutterbar over fenders on a car hauler trailer and save renting the deckover? Again thanks to all.

Thanks to all. Discbinedr - about what size is the longer pin I'll need?

Lifting the tongue will cause the machine to pivot on the axles right? Will the cutter bar or head stay in contact with the trailer floor while lifting the tongue? If not - do I chock it as I lift the tongue? I need to go look at the machine with your suggestions as I'm doing this from memory. Think there would be clearance to get cutterbar over fenders on a car hauler trailer and save renting the deckover? Again thanks to all You need a pin long enough to safely wrap a chain around.

Remember, you're not lifting the tongue, you're lifting the front of the header at the tilt bracket to take the pressure off the tongue. Volvo saildrive parts. The header will likely rise up off the deck and bit, that is why I said to chain it down at the axles. Rent the deck over trailer.